Onsite Wastewater Treatment: Improve Your Process While Cutting Costs

It’s a constant balancing act: your company values environmentally sustainable practices, but they always seem to come at a cost. In the current landscape, plant operators are hyper aware of cost savings. How can we get the results we want at a cost that makes sense? Or even better, how can we actually save money in the process? The answer might lie somewhere a little unexpected: onsite wastewater treatment.

You may have already looked into it and found it was expensive with a high CapEx, operating costs, large potential footprint and necessary new hires. It bumped up electricity costs, required extensive chemicals or constant sludge management. Or maybe you haven’t tried onsite wastewater treatment yet and it seems like a headache to manage. You’re in the business of bottling beverages, brewing beer, packaging or processing food, not in the business of wastewater treatment.

We know. Wastewater treatment is not easy. But how about taking a second look?

Many traditional treatment options are not meeting their treatment objectives, and they are typically not scalable and challenging to manage. So instead, we settle on paying high surcharges, trucking wastewater offsite for disposal or treatment options that no one is quite happy with. But thanks to new technologies, now is the time to revisit your options.

The Status Quo Just Isn’t Working

Staying just above compliance is a risky practice when your facilities are operating with inadequate treatment systems or looking to expand production. This can lead to a number of problems, including non-compliance with regulations, environmental pollution, increased costs, and even business continuity risks and negative public perception.

There are a number of reasons why "good enough" isn't enough when it comes to wastewater treatment. First, regulations are constantly changing, so what was considered "good enough" a few years ago may no longer be acceptable. Second, new technologies are becoming available that can improve the efficiency and effectiveness of wastewater treatment. Third, the cost of environmental compliance is rising, so facilities that are not operating at peak efficiency are at a competitive disadvantage.

Being compliant doesn’t mean you shouldn’t look for new technologies. Quite the opposite - we believe leaders in water stewardship will stay ahead by looking for ways to continuously improve by seeking out new technologies.

The Current Landscape

Surprisingly, little has changed in the field of biological treatments. For the past 50 years, wastewater treatment of organic streams broadly fits into two categories.

Aerobic processes

Aerobic processes are biological treatment processes that require oxygen to remove organic matter from wastewater. However, aerobic processes are energy-intensive, generate large quantities of sludge or biomass, and require a large footprint. These typically are best for lower concentration streams, and can get to a cleaner effluent.

Anaerobic digestion systems

Anaerobic digestion systems are biological treatment processes that do not require oxygen. These systems are used to convert organic matter into biogas, which can be used to generate electricity or heat. Anaerobic digestion systems are less energy-intensive than aerobic processes, and can handle much higher loads. However, they require careful nutrient dosing and a skilled treatment operator.

Both methods have sustainability challenges

The water and wastewater industry is energy intensive, accounting for 4-5% of global greenhouse gas (GHG) emissions.

Even though wastewater has enough energy potential to be carbon neutral, current technologies have inefficiencies in terms of sustainability and water usage. Aerobic processes are blowing oxygen through water, which requires high energy consumption, and they generate large quantities of sludge, which breaks down into methane, a greenhouse gas 84 times more potent than CO2. With anaerobic digestion systems, these are typically considered a sustainable source of renewable natural gas which can offset energy demands of the facility, but in many cases, the methane is flared, which leads to high GHG emissions.

When it comes to water consumption, companies have been reducing water use ratio for decades, but as they reduce water, the resulting wastewater becomes more concentrated. Sometimes this higher concentration at the end of pipe results in treatment upsets. In this case, the only choice is to dilute higher strength streams, adding clean(er) water or sidestream and truck the higher-strength streams offsite. Dilution runs counter to the goal of overall water reduction, but is often the only choice.

There are new alternatives that can not only make your wastewater more sustainable, but significantly reduce costs and water usage as well.

Off-Site Treatment Isn’t the long term Solution

Hauling wastewater offsite for treatment can be a costly and risky proposition. While hauling wastewater may be a cost-effective solution for small companies, it can become prohibitively expensive as the company grows. The cost of hauling wastewater can be significant, especially for large companies. There is always the risk of a spill, which can have environmental and financial consequences. It’s also not sustainable. Hauling wastewater contributes to greenhouse gas emissions and other environmental problems.

Rethinking On-site Treatment

Onsite or point source treatment brings its own series of challenges. The installation of traditional onsite systems alone can cost hundreds of thousands to millions of dollars, depending on the size of the operation. Hiring operators and ongoing maintenance further add to the expenses. Even after investing in onsite systems, some facilities may still have to rely on off-site trucking due to scalability limitations or challenging streams.

Furthermore, the most common approach to handling wastewater treatment presents another obstacle. These systems combine all wastewater into a single large flow, assuming consistent flow and concentration. However, the realities of a manufacturing plant are that production upsets happen, causing spikes in concentration and ultimately upsets in the downstream treatment, which prefer consistent feedstock in terms of pH, organic carbon, temperature and flow. To counter this, companies resort to diluting high-strength streams with fresh water, which requires more energy, prolongs treatment time, and reduces overall system efficiency.

This issue is problematic as it contradicts companies' goals of reducing water use ratio and incurs additional costs, energy consumption, and chemical usage.

We think there’s a better way to approach wastewater treatment.

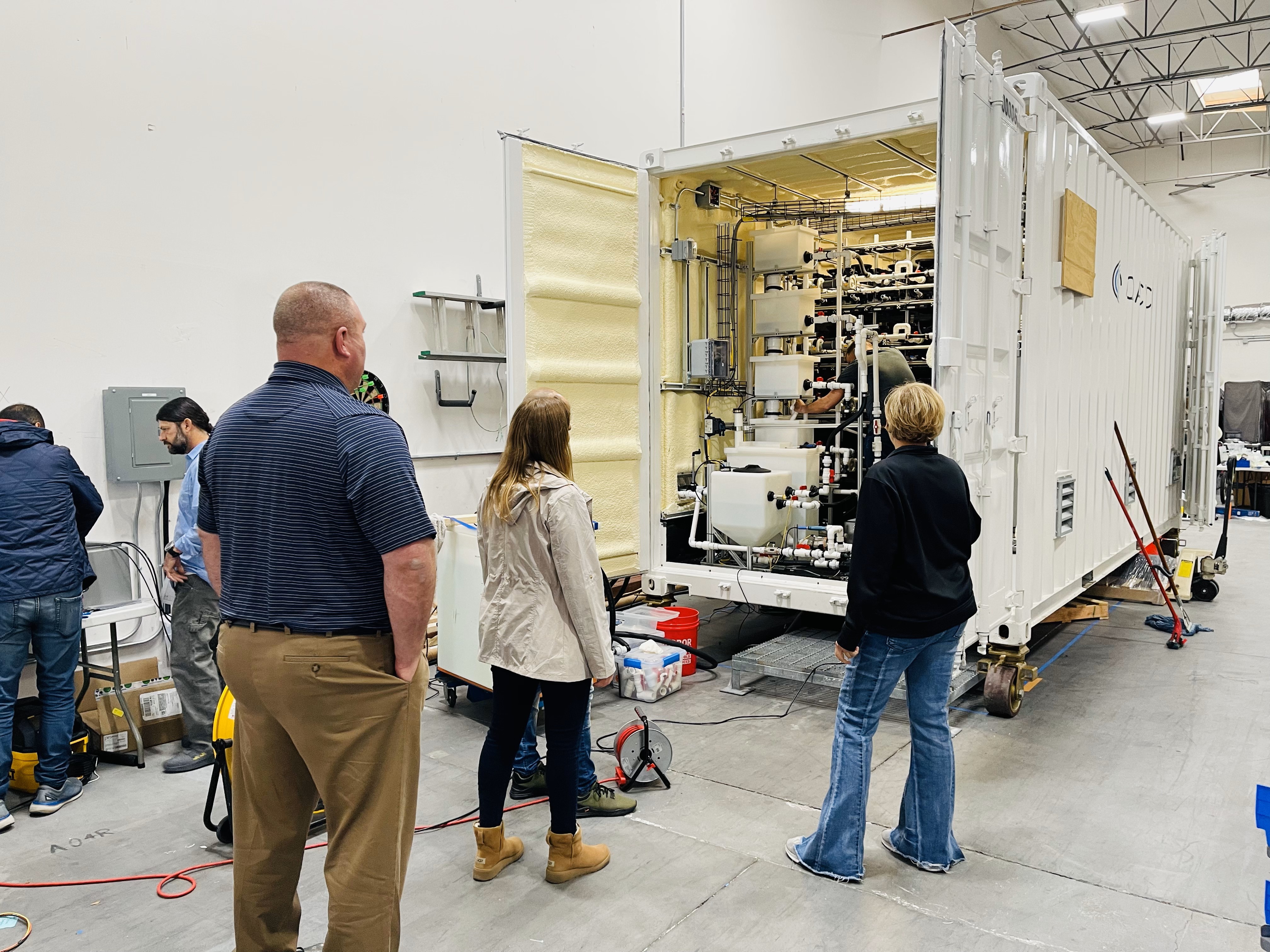

Meet BETT®

Aquacycl uses a system called BETT, or BioElectrochemical Treatment Technology. The core component of the BETT looks like a little black box and is rethinking the way companies manage wastewater. This system works with naturally existing bacteria already present in the wastewater being treated, taking advantage of those microbes, using them to produce electricity. By utilizing electricity production, we are able to monitor and control each reactor remotely in real-time, allowing adjustment of the treatment rate. This means what would take weeks for other systems to treat can be done in a matter of hours.

Aquacycl gives you the ability to treat super high-strength wastewater that is currently untreatable with traditional wastewater treatment. Instead of treating all wastewater, you can focus on treating high concentrations of low-volume streams. We’ve found these streams are usually the costliest and most challenging part of your wastewater management. By treating these small, but challenging streams onsite, you can eliminate sewer surcharges and the need for trucking as well as other benefits such as reduced sludge, shorter treatment times, and a smaller footprint. Consider these benefits and how they can improve your company's profitability and sustainability:

- Eliminate sewer surcharges - one of our customers found that less than 5% of the volume was accounting for over 50% of wastewater surcharges. We provide guaranteed permit compliance and predictable costs based on how much organic carbon is removed.

- No more trucking wastewater - trucking your process wastewater can be a logistical headache, from coordinating the trucks in and out of your facility to relying on an outside trucking company to be able to handle your volume of wastewater. In addition, you run the risk of potential spills or problems during the trucking and often the disposal via trucking is not the most sustainable option. The trucks themselves emit greenhouse gas, as do several options of disposal. The logistical and sustainability concerns can be addressed by onsite treatment with the BETT system. Since the process happens directly onsite, there’s no longer the same need for trucking.

- 80% Primary Sludge Elimination - The fuel cells within each of the BETT boxes transform natural bacteria into powerhouses that clean wastewater while generating small amounts of electricity. The faster we remove the electrons from them, the faster they treat the wastewater. The added benefit is their metabolism is going into eating the carbon in the wastewater and they produce a small fraction of the sludge.

- Reduced energy consumption - Sustainability is core to Aquacycl’s mission. We were founded with a mission of off-sewer and off-energy grid sanitation, and the patented BETT system is the backbone to achieving this. While BETT cannot yet fully power itself, every one of Aquacycl’s clients has reported significantly reduced power consumption for the system compared to alternative treatment systems. At one customer site using the BETT system, they are treating with 60 kWh per day (which is about the greenhouse gas emissions of two passenger cars on the road for an entire year) what would normally take 2,500 kWh per day.

- Wastewater treatment as a service - Familiar with SaaS? Meet WTaaS. Aquacycl’s Wastewater Treatment as a Service solution enables your company to enjoy all the benefits of an onsite wastewater treatment facility without any of the operational responsibilities. This service includes all the necessary monitoring, operations and maintenance that might be required across the contract's lifetime. This service can save companies of all sizes hundreds of thousands of dollars in costs associated with personnel & training, sewer surcharges, chemicals, and disposal fees while simultaneously delivering the benefits of the BETT system.

- We work with whatever equipment you have onsite to make it more efficient. No need to rip and replace your existing system; we can be used as pretreatment to reduce energy usage, chemicals, and treatment upsets. We help you get the most out of whatever is already there.

BETT is Scalable

Many companies continue to pay high sewer surcharges or truck wastewater because it is what’s always been done. Maybe a new system is not worth the cost or the effort of the day-to-day management and operations of an onsite system. Maybe the pain of trucking or off-site wastewater management isn’t enough to change yet.

Enter the beauty of BETT’s modular design. These reactors were designed similar to building blocks or LEGOs in that they can effectively be stacked together. When your facility finds itself expanding capacity or needing to treat additional volume, another container can simply be added to accommodate demand.

BETT is Sustainable

Not only can the improved onsite wastewater treatment of BETT help you with costs and scalability, it can also improve sustainability efforts for your company. BETT is designed to address water scarcity, water quality, and greenhouse gas (GHG) emissions. By treating wastewater at the source, BETT reduces the need to use energy-intensive processes at the downstream utility and enable water reuse for applications requiring lower-quality water, such as cooling towers, boilers, and irrigation. Other specific environmental impact areas include eliminating GHG emissions related to trucking sludge and wastewater.

BETT is also the only treatment technology that can address ultra-high strength streams (up to 150,000 mg/L Biological Oxygen Demand or BOD) and does not produce methane, instead generating DC power to offset the energy demand of the system.

The proof is in the data. Once installed, our team can get you effective numbers that you can then share with your board and clients, showing improved environmental and operational performance. It's easy, effective, and good for the planet - and your company.

Let’s Talk

The Aquacycl BETT System is revolutionary. The cost savings of onsite wastewater treatment with our system outshines any outsourcing or off-site treatment solutions. While we do use the term "revolutionary," Aquacycl is not an untested company. We’ve had commercial systems operating onsite at multinationals like PepsiCo for over 2 years and conducted multiple paid demonstrations, across a variety of areas such as agriculture, distilleries, breweries, military, confectionery, beverage, and tank terminals, where treatment rate exceeded agreed KPIs.

Of course, we understand that seeing is believing. Schedule a meeting with our wastewater consultants to learn more about our system and to see just how it can help you address costs and sustainability.